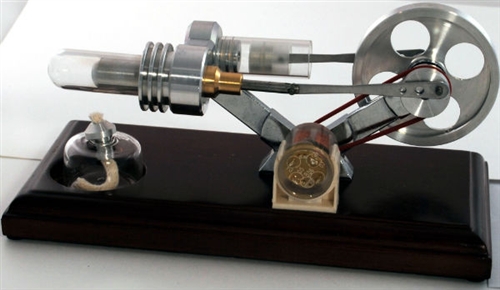

Stirling Engine and its operation

Version Stirling engines are intriguing and exciting to create…but they could be difficult to recognize. If you’re enthusiastic about model Stirling engines but aren’t positive just what they are or why they’re so excellent, this information will answer a few of the questions you have.

The Stirling engine is named for its inventor, Robert Stirling. It really is a shut down-routine regenerative heat engine. It functions by cyclically compressing and growing air flow or another gasoline referred to as the functioning water at diverse temp levels. The temperature energy made makes the engine operate.

A Stirling engine is undoubtedly an exterior combustion engine, like a steam engine. Which means that each of the engine’s heat should go in and out throughout the wall structure of your engine, from an external source of heat? But unlike a water vapour engine, which utilizes water within both liquid and gas form, Stirling engines only use the fuel kinds of fluids including hydrogen, helium or o2. This functioning water is compressed, warmed up, widened, after which cooled yet again within a continuous routine.

Stirling engines contain a repaired level of doing work liquid. The engine is enclosed, so not one of the fuels leaves the engine, and nothing enters from the outside. Once you have a set level of petrol within a repaired quantity of area, rearing the temperatures from the petrol will increase its strain. Should you compress the petrol, its temperatures may go up. The petrol is moved back and forth involving hot and cold heat exchangers. To get it just, a fundamental Stirling engine operates this way:

- A very hot temperature exchanger a heated up tube is open to another heat source, which then heats up the petrol in this cylinder to result in pressure of the gas to improve. This improved kit scientifique helps make the piston from the heated up tube relocate down and do work.

- The piston on the opposite side movements as one other movements lower, and that then pushes the warmed gasoline in to the cool warmth exchanger, or frosty tube. The frosty tube is cooled by the background temp of your surrounding environment or by an external method to obtain chilly. Since the petrol cools, its stress is minimized and it also becomes simpler to compress.

- The piston inside the chilly tube then movements down and squeezes the cooled gasoline. Any heating generated by the compression is taken off through the cooling source referred to as heat kitchen sink.

- The piston inside the warming cylinder moves up, and gasoline is forced rear within the heated cylinder. Since it heats up pressure improves, the piston techniques downward, and the period repeats repeatedly.

Normally a regenerator is positioned in between the heated place along with the air conditioning location. This behaves as a warmth store and raises the engines effectiveness by retaining and trying to recycle the heat that passes throughout the engine, as opposed to letting it minimize, click now https://www.lesdiy.com/collections/maquette-avion-bois.